What Is Supply Chain Integration?

- 17/10/2022

- Philip K

To recover from the large-scale global supply chain, it is very important to choose a supply chain strategy.

What is Supply Chain Integration?

Horizontal integration refers to the activities in the supply chain, from raw materials to consumers, including the change and flow of goods, and the generation, storage, and flow of related information, planning, organizing, and controlling the activities in the supply chain.

Vertical integration refers to the effective integration of suppliers, factories, warehouses, and shops. The manufacturing and distribution of products are carried out in the correct quantity, time, and place to meet the needs of customers and minimize the system cost.

What are the Benefits of Supply Chain Integration?

How to Integrate Your Supply Chain?

Do you need to reduce procurement costs, align business objectives with partners, acquire businesses to improve market dominance, and speed up delivery time and reliability? The defined integration goal should guide the whole supply chain integration process.

How does information flow between businesses and different links in the supply chain? How and how fast does the cash flow between partners flow? Identify bottlenecks, communication barriers, slow suppliers, overpriced suppliers, and problems that interfere with business efficiency and profitability.

Determine whether the supply chain integration goal is best achieved through horizontal integration, vertical integration, or both:

Horizontal integration: Horizontal integration involves a company buying a company to eliminate competition and immediately expand its customer base, or a partnership in which each company agrees to focus on a specific market segment or geographical area.

Vertical integration: Vertical integration involves the business purchase or partnership with widget manufacturers to improve integration and efficiency and ensure fair widget prices and timely delivery.

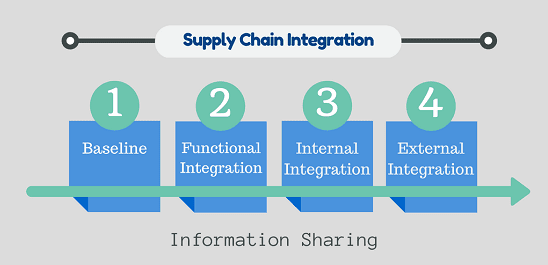

The following four levels of integration are provided:

Baseline: Maintain isolated information within each department or “supply chain link”.

Integration: All information is shared equally throughout the supply chain. The goal of information sharing is to improve the efficiency of the supply chain.

Internal integration: Information is shared among all departments and organizations that make up the supply chain. Each department or organization operates as an independent and independent unit.

External integration: An alliance involving departments or companies that make up the supply chain.

Taylored service is a fully integrated 3PL provider, engaged in wholesale, retail, and direct performance to consumers. Cooperate with full-service integrated logistics providers such as Taylored Services to help e-commerce enterprises of all sizes effectively provide services to customers, allowing companies to expand when needed, without a large investment.

Conclusion

With the passage of time, the influence of choosing an appropriate supply chain strategy is constantly evolving. The push-pull strategy in supply chain operation has unique advantages and functions for the supply chain operation of enterprises. The possibility of using a hybrid model is also important.

As the world recovers from the large-scale global supply chain, it is very important to choose a supply chain strategy. Choose a specific supply chain strategy to meet the needs of customers and push the business forward! If you want to know more, you can contact us!

Supply Chain Integration FAQ

What is an example of supply chain integration?

What are the six types of integration in supply chain management?

Need a Quick Quote?

– Competitive price

– Quote within 24 hours

– 30+ Shipping methods

– Dedicated account manager

– Shopify/Woo integrations

– Autofulfil

– Auto tracking

– Plus much, much more

5 Best Wholesale Home Decor Suppliers 2023

10 Best Bikini Brands For Summer 2023