One-Stop-Shop

Making China sourcing and fulfilment easy, we remove the frustrating language, communication & cultural barriers you’ve come to expect. Fully integrated eCommerce fulfilment services that include product sourcing, branding and distribution. What sets us apart is the ability to offer our complete eCommerce fulfilment service or one of our specialist services. Whatever your business requires, we can provide a fulfilment solution that is tailored to your situation and requirements.

Our Services

Dropshipping Services

2PL International Logistics

Storage & Warehousing

Product Inspection & QC

3PL Worldwide Fulfilment

Packaging, Branding & Assembly

eCommerce Dropshipping

Product Photos & Videos

Product Sourcing

SEAMLESS INTEGRATION WITH YOUR STORE

Warehousing & Delivery

- Global Storage Locations

- 3 Months Free Storage

- Quality Contro659]+l As Default

- Global Delivery

- 18+ International 3PL Warehouse Locations

Automated Order Processing

- Create Bundles & Offers

- Streamlined Autofulfil

- Process Orders With One Click

- Stock & Price Notifications

- Wholesale Pricing

- Bulk Orders

- PayPal Tracking Update

Online Shipment Tracking

- End to End Shipment Tracking

- Manage Multiple Shopify Stores

- Automatic Update of Tracking Numbers

- Customizable Tracking URLs

- Selection of 20+ Shipping Services

- Shipping Charged at Cost Price

- Fully Automated

3PL Optimization

- Account Manager

- Logistic & Freight

- Paypal Tracking Update

Product Management

- Find Import Information

- Custom Packaging

- Product White labeling

TESTIMONIALS

– Sandra Ball

TESTIMONIALS

– Mohammed Khan

TESTIMONIALS

– Amanda Ellis

TESTIMONIALS

– Diegro Morales

Unlimited Scalability

As your business grows, our fulfilment solutions can adapt to cater for your changing volumes and requirements. The eCommerce supply chain is a complex system and any changes to a specific step produce a knock-on effect on all other move parts and can cause many issues.

Therefore, it is vital to have a flexible eCommerce fulfilment partner who can adapt effectively and efficiently to grow your business.

Unlimited Scalability

As your business grows, our fulfilment solutions can adapt to cater for your changing volumes and requirements. The eCommerce supply chain is a complex system and any changes to a specific step produce a knock-on effect on all other move parts and can cause many issues.

Therefore, it is vital to have a flexible eCommerce fulfilment partner who can adapt effectively and efficiently to grow your business.

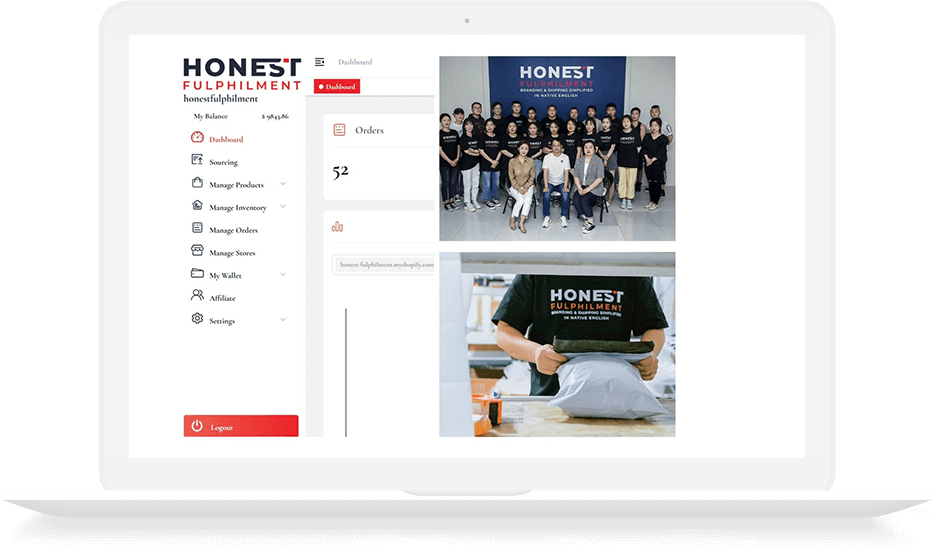

Connect Your Stores

In-house developed Shopify & WooCommerce app automates order processing, keeping your customers happy and up to date with tracking and delivery.

Check your sales, production, inventory, costs, margins, and much more, all in one place.

Your Trustworthy

Partner

At Honest FulPhilment, we have been providing our services to customers all over the world, for years. Not only do our clients rave about us, but we have also built strong relationships with many production companies in China along with a long list of international logistics partners.

Hassle-Free Fulfilment

WIth 18 international warehouses, we help you ship from China, or your domestic market.

Our aim is to provide you with a solution at the best possible value with full transparency and zero drama. Years of systems and processes help us do this in the most efficient way possible.

Latest Blog

5 Best Wholesale Home Decor Suppliers 2023

Want to start dropshipping home decor now? Great! Americans spend an estimated $185 billion a year on home improvement. Yes, huge! And according to Statista, the value of the home décor market in the United States is expected to reach $202 billion by 2024. Therefore, having the right supplier is essential if you want to […]

How To Find Winning Products For Dropshipping In 2023

Is your dropshipping store unprofitable and barely breaking even? If so, now there is the best solution to help you double your profits – find winning products. If you are new to e-commerce, finding winning products to sell in your online store can be a difficult process for you. This is because you have to fill your […]

How To Find Private Label Jewelry Manufacturers To Dropship?

Do you want to expand your jewelry dropshipping business through private labeling? Private label jewelry allows you to create your own brand and offer a unique product to your customers. If you want to venture into the world of dropshipping private label jewelry, it is crucial to find reliable manufacturers. In addition to checking out […]

10 Best Bikini Brands For Summer 2023

You may already own a normal swimsuit or one-piece, but your wardrobe is missing summer and beach must-have——the bikini. No matter who you are, there’s no limit to what you can try on bikinis. There are many styles of bikinis, from classic styles to trendy bikinis, from full coverage to extreme revealing… And which bikini […]

Best Fitness Clothing Manufacturer For Your Dropshipping Business

Finding a fitness clothing manufacturer isn’t difficult. You can find hundreds online. But the hardest part is finding the best gym clothing manufacturers that work best for your business. Especially when it comes to creating your own activewear brand. I recommend you check out the following list of 5 fitness and activewear manufacturers. They not […]

10 Best Jewelry Dropshipping Suppliers In 2023

Jewelry is one of the most popular and lucrative niches in the e-commerce market. With the rise of online shopping, more and more people are buying jewelry online. The dropshipping model is an excellent choice for jewelry dropshippers who want to enter the jewelry e-commerce market but do not have a large capital investment. However, […]

eCommerce Fulfilment Services

We have a range of eCommerce fulfilment services that we offer to our customers. This includes product sourcing, packing and shipping, inventory storage, branding and international distribution and shipping services. All of our services are provided with our excellent customer service and include integrations with your eCommerce platform which is updated in real-time.

Product procurement

Packaging

Transportation

Inventory storage

Stress-Free Fulfilment To

Grow Your Business & Make

Your Customers Happy

Stress-Free Fulfilment To

Grow Your Business & Make Your Customers Happy

FREE FULFILMENT STRATEGY

Our Testimonials