We protect you from inferior products and nasty surprises for your B2C & B2B orders.

Quality control and inspection are a must in any industry, especially when you’re dropshipping products from China. Without such protocols, you run the risk of receiving bulk shipments of goods, not only utterly different to what you ordered or were expecting but arriving damaged and unusable. If this occurs, the chances of claiming reimbursement or replacements will be highly unlikely.

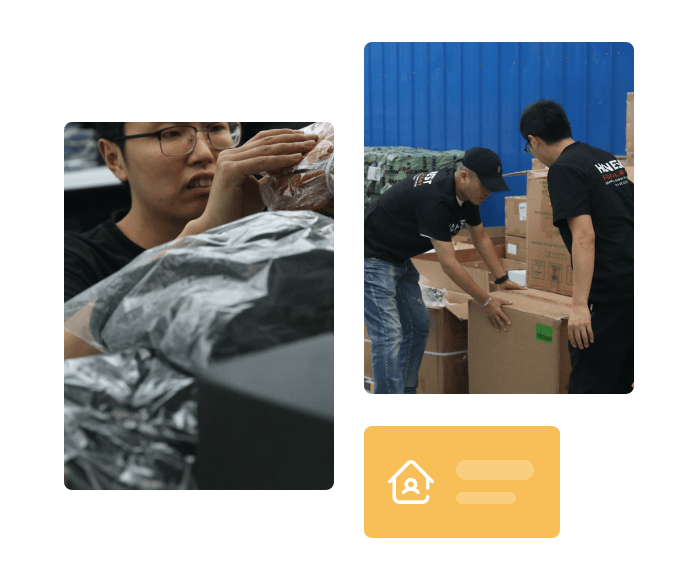

At Honest FulPhilment, regardless of the service you’re utilising, we set product inspection and quality control as a priority. Product inspection in the wrong hands and with inexperience, failure to inspect or quality control could ruin your business.

Product inspection is very rarely a simple process. With the vast spectrum of products available on the market, each having its respective features and practical usage, the inspection process is often unique in each case.

One product could require a basic visual inspection, whereas another requires an electrical current safety test, stress test, drop test, specification check, and endless other checks and tests.

You may have specific requirements that you’d like us to carry out, but whatever the test, everything is documented, with photos and videos assigned to each element and phase.

This is where procedures play an important role. Be it pre-production, during production, production monitoring or pre-shipment inspection, each has its own unique process where we give you full control, keep you in the loop and do not move forward until your final confirmation.

Through years of experience in trading and partnerships, we have learnt that it doesn’t matter if working with manufacturers, wholesalers, resellers or suppliers in general, where there is a transaction, no matter how insignificant of sum it may be, quality control of some kind must be upheld to guarantee quality and satisfaction for our clients.

Here are some examples of why you may require help with product inspection:

You are searching for a dropshipping or 3PL agent to handle your eCommerce orders, with the added benefit of inspecting 100% of goods that we pack pre-dispatch directly to your customers.